|

| January 07, 2020 | Volume 16 Issue 01 |

Materials News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Weird stuff: Moon dust simulant for 3D printing

Crafted from a lunar regolith simulant, Basalt Moon Dust Filamet™ (not a typo) available from The Virtual Foundry closely mirrors the makeup of lunar regolith found in mare regions of the Moon. It enables users with standard fused filament fabrication (FFF) 3D printers to print with unparalleled realism. Try out your ideas before you go for that big space contract, or help your kid get an A on that special science project.

Crafted from a lunar regolith simulant, Basalt Moon Dust Filamet™ (not a typo) available from The Virtual Foundry closely mirrors the makeup of lunar regolith found in mare regions of the Moon. It enables users with standard fused filament fabrication (FFF) 3D printers to print with unparalleled realism. Try out your ideas before you go for that big space contract, or help your kid get an A on that special science project.

Learn more.

Make nylon 3D-printed prototypes and parts in the office

The new SLS 300 from 3D Systems is an affordable, turnkey, closed-loop 3D-printing system designed to operate in a smaller-footprint environment. SLS 300 makes selective laser sintering available to a broader range of customers with a high-reliability, affordable solution to produce end-use parts. Users can produce tough, durable parts from a range of production-grade nylon materials. Amazing fill, finishing, and clean-up systems.

The new SLS 300 from 3D Systems is an affordable, turnkey, closed-loop 3D-printing system designed to operate in a smaller-footprint environment. SLS 300 makes selective laser sintering available to a broader range of customers with a high-reliability, affordable solution to produce end-use parts. Users can produce tough, durable parts from a range of production-grade nylon materials. Amazing fill, finishing, and clean-up systems.

Learn more.

Will it erode? 3D-printing materials comparison from Xometry

Which 3D-printed plastics are the toughest? In this "Will it ..." video, Greg Paulsen, Xometry's Director of Application Engineering, 3D printed Benchies (3D test models) using different materials (such as polycarbonate, PLA, polypropylene, ULTEM, and Nylon 11 and 12) and processes (such as FDM, SLS, MJF, SLA, LSPc, Polyjet, and DLS) and then ran several abrasion tests on them. Watch to find out which 3D-printed plastic is truly the toughest of them all!

Which 3D-printed plastics are the toughest? In this "Will it ..." video, Greg Paulsen, Xometry's Director of Application Engineering, 3D printed Benchies (3D test models) using different materials (such as polycarbonate, PLA, polypropylene, ULTEM, and Nylon 11 and 12) and processes (such as FDM, SLS, MJF, SLA, LSPc, Polyjet, and DLS) and then ran several abrasion tests on them. Watch to find out which 3D-printed plastic is truly the toughest of them all!

View Part 1.

View Part 2.

Graphene Handbook: Learn all about this wonder material

Metalgrass LTD has published the 11th edition of its "Graphene Handbook," a comprehensive resource on graphene technology, the industry, and the market for this wonder material made of single layers of atoms of pure carbon. The book includes development history, production methods, current research, an intro to metrology and standardization, and even an investment guide. Under 100 bucks for digital edition. Hard copy available too.

Metalgrass LTD has published the 11th edition of its "Graphene Handbook," a comprehensive resource on graphene technology, the industry, and the market for this wonder material made of single layers of atoms of pure carbon. The book includes development history, production methods, current research, an intro to metrology and standardization, and even an investment guide. Under 100 bucks for digital edition. Hard copy available too.

Learn more.

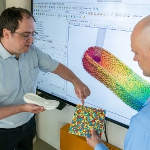

Who knew? How colorants affect plastic

In plastic injection molding, one aspect of polymer characteristics that doesn't always get the consideration it deserves is the addition of colorant. Believe it or not, there is a whole scientific body of knowledge about the ways in which adding color to plastic can affect its behavioral properties. This short article by Denny Scher of ICO Mold takes a high-level look at some of the different, and surprising, ways colorants can affect plastics.

In plastic injection molding, one aspect of polymer characteristics that doesn't always get the consideration it deserves is the addition of colorant. Believe it or not, there is a whole scientific body of knowledge about the ways in which adding color to plastic can affect its behavioral properties. This short article by Denny Scher of ICO Mold takes a high-level look at some of the different, and surprising, ways colorants can affect plastics.

Read the full article.

Retaining magnets from JW Winco: Universal and clever

JW Winco has expanded its magnet line to support more applications with new materials, shapes, systems, and even raw magnets. Learn about their latest offerings, including retaining magnets designed for corrosive environments (GN 50.8), encapsulated magnets designed for sensitive or painted surfaces (GN 51.8), handle magnets (GN 53.3), and powerful magnets designed to handle challenging environs (GN 52.6).

JW Winco has expanded its magnet line to support more applications with new materials, shapes, systems, and even raw magnets. Learn about their latest offerings, including retaining magnets designed for corrosive environments (GN 50.8), encapsulated magnets designed for sensitive or painted surfaces (GN 51.8), handle magnets (GN 53.3), and powerful magnets designed to handle challenging environs (GN 52.6).

Learn more.

3D print tool steel with the ease of a plastic

The Virtual Foundry, a pioneer in advanced 3D-printing materials, is excited to announce the launch of their latest innovation: M300 Tool Steel Filamet™ (not a typo). This material answers the demand for FFF 3D-printable Tool Steel, delivering unparalleled strength and versatility. What sets this material apart is its seamless compatibility with various 3D printers, including Creality, Bambu Lab, Ultimaker, and more. The filament prints effortlessly, resembling the ease of working with PLA (plastic).

The Virtual Foundry, a pioneer in advanced 3D-printing materials, is excited to announce the launch of their latest innovation: M300 Tool Steel Filamet™ (not a typo). This material answers the demand for FFF 3D-printable Tool Steel, delivering unparalleled strength and versatility. What sets this material apart is its seamless compatibility with various 3D printers, including Creality, Bambu Lab, Ultimaker, and more. The filament prints effortlessly, resembling the ease of working with PLA (plastic).

Learn more.

Great Resources: Sheet metal design guide

If you're looking for a basic guide to sheet metal design, this one from Xometry will serve your needs well. Follow the design requirements and tolerances in this guide to ensure parts fall closer to design intent. This is the type of information you'll sock away and then refer to again and again.

If you're looking for a basic guide to sheet metal design, this one from Xometry will serve your needs well. Follow the design requirements and tolerances in this guide to ensure parts fall closer to design intent. This is the type of information you'll sock away and then refer to again and again.

Read the full article.

Particle foam perfectly distributed thanks to simulation with Ultrasim

BASF's Ultrasim simulation solution now includes Infinergy, an expanded thermoplastic polyurethane (E-TPU) that is used in a wide range of applications to make components with particle foam -- from bicycle tires to the soles on shoes. Identify and solve problems related to pneumatic filling when distributing particle foams in molds, even taking gravity and mold closing into consideration. Avoid those pesky air pockets.

BASF's Ultrasim simulation solution now includes Infinergy, an expanded thermoplastic polyurethane (E-TPU) that is used in a wide range of applications to make components with particle foam -- from bicycle tires to the soles on shoes. Identify and solve problems related to pneumatic filling when distributing particle foams in molds, even taking gravity and mold closing into consideration. Avoid those pesky air pockets.

Learn more.

Premium polymer DLP printer is half the price of its predecessor

Desktop Metal has just launched the ETEC Pro XL -- a premium polymer digital light processing (DLP) printer that enters the market at less than half the price as its predecessor. DLP is regarded by many as a superior polymer 3D-printing technology for speed, surface finish, and accuracy. Ideal for automotive and machine parts, aerospace components, housings, connectors, jigs and fixtures, short-run molds, and more.

Desktop Metal has just launched the ETEC Pro XL -- a premium polymer digital light processing (DLP) printer that enters the market at less than half the price as its predecessor. DLP is regarded by many as a superior polymer 3D-printing technology for speed, surface finish, and accuracy. Ideal for automotive and machine parts, aerospace components, housings, connectors, jigs and fixtures, short-run molds, and more.

Read the full article.

CNC machining case study: One-of-a-kind computer chassis

Learn how Josh Sniffen, the YouTuber behind the popular PC-building channel "Not From Concentrate," trusted Xometry to provide a wide range of manufacturing options, personalized Design for Manufacturing (DFM) feedback, and order management support for his latest creation: the HEXO ATX computer chassis. All in all, Sniffen procured parts using Xometry's CNC machining service, selective laser sintering 3D-printing service, and sheet metal cutting and fabrication services. A neat insider look at the process.

Learn how Josh Sniffen, the YouTuber behind the popular PC-building channel "Not From Concentrate," trusted Xometry to provide a wide range of manufacturing options, personalized Design for Manufacturing (DFM) feedback, and order management support for his latest creation: the HEXO ATX computer chassis. All in all, Sniffen procured parts using Xometry's CNC machining service, selective laser sintering 3D-printing service, and sheet metal cutting and fabrication services. A neat insider look at the process.

Read this Xometry case study.

Which parts should be 3D printed? AI combs through CAD files to find out

One of the biggest challenges in transitioning to additive manufacturing (AM) is the ability to identify which parts are best suited for the process quickly and easily. Learn how Danfoss, Stanley Engineered Fastening, and even the U.S. military have utilized advanced additive manufacturing software to automate the process, reducing material waste and energy costs, improving part reliability, decreasing lead times, as well as now having the ability to identify part consolidation opportunities through intelligent AM decision-making.

One of the biggest challenges in transitioning to additive manufacturing (AM) is the ability to identify which parts are best suited for the process quickly and easily. Learn how Danfoss, Stanley Engineered Fastening, and even the U.S. military have utilized advanced additive manufacturing software to automate the process, reducing material waste and energy costs, improving part reliability, decreasing lead times, as well as now having the ability to identify part consolidation opportunities through intelligent AM decision-making.

Read the full article.

9 key design tips for injection molding

Keep costs down and quality up all while optimizing your injection molded designs with these helpful tips from Xometry. Learn how to build better injection molded parts and products -- using draft angles, ribs and gussets, radii, fillets, and more -- and set expectations for the injection molding process. Good info here.

Keep costs down and quality up all while optimizing your injection molded designs with these helpful tips from Xometry. Learn how to build better injection molded parts and products -- using draft angles, ribs and gussets, radii, fillets, and more -- and set expectations for the injection molding process. Good info here.

View the video.

Metal additive manufacturing: Rocket turbopump design

Mixing undergraduate curiosity and real-world engagement, two students from Colorado University Boulder Aerospace Engineering Sciences program, Zachary Lesan and Patrick Watson, started an independent effort on turbopump design and manufacture that is a lesson in determination and industry collaboration. With lots of supplies and advice from industry heavy hitters including Velo3D, CFturbo, SpaceX, and many more, their project has reinforced significant points being made about next-generation rocketry.

Mixing undergraduate curiosity and real-world engagement, two students from Colorado University Boulder Aerospace Engineering Sciences program, Zachary Lesan and Patrick Watson, started an independent effort on turbopump design and manufacture that is a lesson in determination and industry collaboration. With lots of supplies and advice from industry heavy hitters including Velo3D, CFturbo, SpaceX, and many more, their project has reinforced significant points being made about next-generation rocketry.

Read the full article.

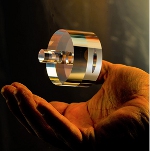

Transparent ceramics for extreme optics

Sapphire is an inherently transparent ceramic material that is resistant to extremes of temperature and environment. Sapphire can be processed to unique and precise shape/form by diamond grinding and polishing to allow full transparency. INSACO is a global leader in this capability -- and working with ultra-hard materials in general.

Sapphire is an inherently transparent ceramic material that is resistant to extremes of temperature and environment. Sapphire can be processed to unique and precise shape/form by diamond grinding and polishing to allow full transparency. INSACO is a global leader in this capability -- and working with ultra-hard materials in general.

Learn more.

Diesel gets way cleaner with new injector technology

An engine innovation first conceived and tested by Sandia National Laboratories has attracted the attention of big business because of its potential to reduce emissions of soot and nitrogen oxides cost effectively, encourage the use of renewable fuels, and maintain or improve engine performance.

Ducted fuel injection, developed by Charles Mueller at Sandia's Combustion Research Facility, is able to fine-tune the fuel-air mixture in an engine to the point of eliminating between 50 to 100 percent of the soot depending on the engine's instantaneous speed and power level.

Mueller said engine manufacturers are "starting to show excitement" about ducted fuel injection. Not only does it work well with conventional diesel fuel, it is conceptually simple and can be constructed from low-cost materials.

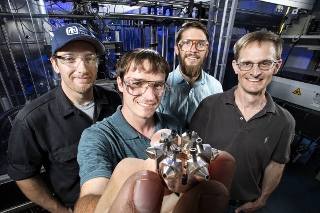

Sandia National Lab researchers, from left, Nathan Harry, Christopher Nilsen, Drummond Biles, and Charles Mueller, show off the prototype ducted fuel injection module. [Photo by Randy Wong]

"Ducted fuel injection is also conceivably retrofittable onto existing engines," Mueller said. "This is especially important for large engines, like those in ships or locomotives, where the engines can cost a million dollars or more, and full electrification is cost prohibitive. A retrofit could be relatively inexpensive and could provide substantial emissions benefits right away."

Humble beginnings: Idea for ducted fuel injection came from Bunsen burner

Ducted fuel injection was first conceived by Mueller from -- of all things -- a Bunsen burner, which can be found in almost every high school science classroom in the nation.

"If you unscrew the tube on a Bunsen burner and you light the gas jet, you get a tall, sooty orange flame," Mueller said. "Turn off the gas, screw the tube back on and re-light the burner. Now you get a nice, short blue flame right at the end of the tube. The flame is blue because there isn't any soot."

Mueller thought that concept might be adaptable to combustion engines, so he and his team -- intern Christopher Nilsen, post-doctoral appointee Drummond Biles, and technologist Nathan Harry -- began experiments that have now resulted in an assembly of four to six small tubes -- or ducts -- directing fuel mixture from the injector to the points of ignition.

Mueller says that injectors in a traditional diesel engine create local igniting mixtures that contain two to 10 times more fuel than is needed for complete combustion.

"When you have that much excess fuel at high temperature, you tend to produce a lot of soot," he said. "Installing the ducts enables us to achieve diesel combustion that forms little to no soot, because the local igniting mixtures contain less excess fuel."

Limiting the formation of a universal engine pollutant

Generations of engine designs have failed to take soot out of emissions because there was a physical limit to the chemistry of fuel combustion.

"Soot is second only to carbon dioxide as a chemical that forces climate change, and it's toxic, so its emissions should be minimized," Mueller explained. "In the past, there's always been this problem called the soot-NOx tradeoff. That is: When you do something to lower soot, emissions of nitrogen oxides -- or NOx -- go up, and vice versa."

Nitrogen oxides are also atmospheric pollutants, and the tradeoff meant that truck, car, and equipment makers couldn't meet current legislated limits without adding exhaust-gas aftertreatment systems. These systems are analogous to catalytic converters on spark-ignition engines, though significantly larger and more expensive. But remove one of those pollutants almost entirely -- like ducted fuel injection does with soot -- and Mueller said you have changed the game.

"Now that we've got soot out of the way, there's no more soot-NOx tradeoff," he said. "So, we can add dilution -- taking some of the engine exhaust and routing it back to the intake -- to get rid of NOx without soot emissions becoming a problem. It's like a two-for-one deal on reducing pollutants."

Mueller said that in engine experiments, his team has observed simultaneous, orders-of-magnitude reductions in soot and nitrogen oxides.

"This gives us a path to much lower emissions for diesel engines, solving a long-standing problem for this highly efficient technology," he said.

Reducing trucking costs with ducted fuel injection, renewable fuels

The near elimination of soot and nitrogen oxides may also open up the market for renewable fuels.

"Ducted fuel injection works great with conventional diesel fuel, but it works even better with oxygenated fuels, which have one or more oxygen atoms bonded into some or all of their molecules. Many renewable, sustainable fuels are oxygenated," Mueller said.

"Using oxygenated fuels with ducted fuel injection lowers emissions, perhaps enough to enable a less expensive engine system because less exhaust aftertreatment would be required," he said. "On a modern on-highway truck, aftertreatment amounts to about $12,000 in initial and operating costs over the life of the vehicle. Reducing even a fraction of those costs is a big deal, given the large number of these vehicles and their importance to the economy."

Technology promises vehicle, alternative-fuel market opportunities

Paul Miles, manager of the engine research program, said the potential impact of ducted fuel injection cannot be overstated.

"Breaking the tradeoff between soot and nitrogen oxides is a research area of highest priority for diesel engine development," Miles said. "This is an example of the key role of government-supported research to identify and demonstrate the potential of innovative, high-risk technologies to reshape the landscape for an industry, our transportation infrastructure and our society, and then to work alongside commercial partners to get the technology into the marketplace."

Ford and a manufacturer of off-road equipment recently signed a cooperative research and development agreement with Sandia to help advance the technology.

Mueller is excited about collaborating with industry partners to move this breakthrough from the laboratory toward production engines.

"Ducted fuel injection shows promise for giving us clearly superior engines for the future," he said. "It should preserve all of the desirable attributes of a conventional diesel engine but also significantly lower the emissions, which lowers the cost of the engine system because you don't have to use as much aftertreatment. And, it works even better with current and emerging renewable fuels."

This research was conducted as part of the Co-Optimization of Fuels and Engines program sponsored by the U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy, through the Vehicle Technologies and Bioenergy Technologies offices.

Sandia National Laboratories is a multimission laboratory operated by National Technology and Engineering Solutions of Sandia LLC, a wholly owned subsidiary of Honeywell International, for the U.S. Department of Energy's National Nuclear Security Administration.

Source: Sandia

Published November 2019

Rate this article

View our terms of use and privacy policy